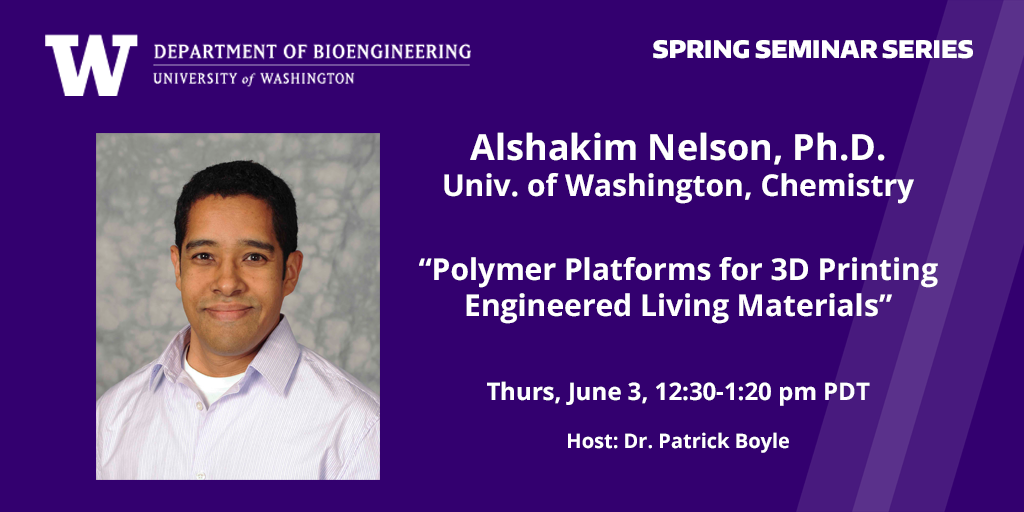

Polymer Platforms for 3D Printing Engineered Living Materials

Speaker Details:

Dr. Alshakim Nelson

University of Washington

Lecture Details:

June 3, 2021

12:30 p.m. - 1:20 p.m.

Associate Professor of Chemistry; Director of Education, UW Molecular Engineering and Sciences Institute

Register for this Webinar

Abstract:

The convergence of synthetic biology with polymer science has led to the rapid emergence of engineered living materials (ELMs), which are composite materials of engineered cells encapsulated within a polymeric matrix. ELMs have the potential to attain a level of precision, control, and sustainability that is not achieved with traditional abiotic materials. While the minimum requirements for fully living ELMs are cell viability and metabolic activity, the integration of ELMs at their fullest potential in future biomanufacturing also requires processing into desired form factors and spatial control over multiple engineered cell populations.

Additive manufacturing (or 3D printing) has re-emerged into the spotlight in the last 10 years driven by the rapid progress in hardware and software. While off-the-shelf polymeric materials have been utilized as inks and resins for additive manufacturing, there is still a need to develop functional materials that are specifically designed for these processes. In this seminar, I will present two different polymer platforms that we have developed to 3D print ELMs. In the first part of my seminar, I will discuss the development of stimuli-responsive triblock copolymer hydrogels for fabricating immobilized cell bioreactors. These hydrogels were used to incorporate engineered microbes that served as cellular factories for the on-demand bio-production of chemical products. In the second part of my seminar, I will discuss a two-step additive manufacturing process to fabricate protein-based constructs using a commercially available laser-scanning SLA printer. Methacrylated bovine serum albumin (MA-BSA) was synthesized and formulated into aqueous resins that was used to print complex 3D geometrical constructs with a resolution comparable to a commercially available resin. Compression studies of hydrated and dehydrated constructs demonstrated a broad range of compressive strengths and Young’s moduli that could be further modulated by adjusting the type and amount of co-monomer. These protein-based matrices served as biodegradable scaffolds for 3D printing ELMs, and I will present strategies for fabricating bio-augmented and bio-sustained ELMs.

Speaker Bio:

Alshakim Nelson is an Associate Professor of Chemistry and the Director of Education at the Molecular Engineering and Sciences Institute at the University of Washington. He received his PhD in organic chemistry from the University of California, Los Angeles in 2004, where he worked with Sir J. Fraser Stoddart on carbohydrate-containing polymers and macrocycles. He was then an NIH postdoctoral fellow at the California Institute of Technology working for Professor Robert Grubbs on olefin metathesis catalysts for the formation of supramolecular ensembles. Dr. Nelson was a Research Staff Member at IBM Almaden Research Center for 10 years where he focused on the synthesis of nanomaterial building blocks that enabled large area nanomanufacturing via self-assembly. In 2015, Dr. Nelson joined the faculty at the UW, where his research group focuses on the synthesis, characterization, and processing of stimuli-responsive materials for 3D printing. Dr. Nelson has over 70 publications and 25 issued patents. His honors and awards include recognition as an IBM Master Inventor, ACS PMSE Young Investigator, Kavli Foundation Fellow, NSF CAREER award, and 3M Non-Tenured Faculty Award.