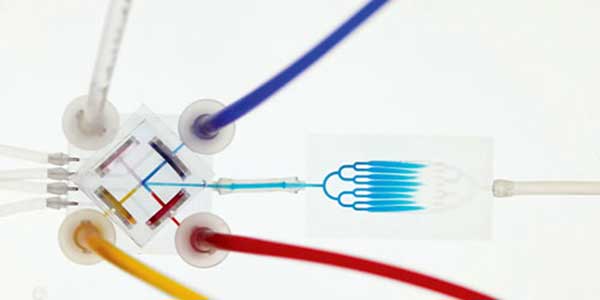

Image: A 3D-printed four-valve switch (left) is shown connected to a 3D-printed cell culture chamber (right). Each valve is pneumatically operated through one of four dedicated tubes, each of which contains a different food-coloring dye. Only the blue-dye valve is open. Anthony Au, Ph.D., and Albert Folch, Ph.D., University of Washington.

UW Bioengineering Associate Professor Albert Folch’s research was featured in a recent article, “3D Bioprinting Revolution Solidifies Gains,” in Genetic Engineering & Biotechnology News. The article discusses novel emerging applications of 3D printing for applications in biotechnology and medicine, including microfluidics, biodegradable medical devices and printing human tissues for transplant.

“3D printing provides the flexibility to design extremely complex structures at low cost: complexity, variety, and modeling are essentially free. We can understand how it will work before we make it. There is a huge efficiency in design there.” -Albert Folch, associate professor of bioengineering.

Dr. Folch’s research focuses on microfluidic devices for applications in automated cell cuture, neuroscience research, cancer diagnostics and cancer therapy. In the article, he discusses his lab’s work to develop “functionalized chemotherapy” to cancer patients. The technology could allow a patient’s biopsied tissue to be kept alive and exposed to different treatments while the patient recovers from surgery, and show what treatmentes might work to treat that patient’s specific condition. Dr. Folch proposes that this technology may be especially useful in helping physicians select individualized treatments for difficult-to-treat cancers such as glioblastoma.

In the article, he also discusses how his lab is working to resolve some of the challenges with 3D printing. Particularly challenging is the fact that cells will die in a 3D-printed petri dish, he says. His lab is testing biocompatible polymers that could help cells stay alive — and make them widely available to the scientific community. “It is important to develop open-source polymers,” he explains. “They should be accessible.”